Together with Gewobag, we are currently realizing the world's largest residential construction project using modular construction methods.

Your one-stop store

for modular housing projects

Wir kombinieren die Modulbaukompetenz des Weltmarktführeres Daiwa House mit unserem umfassenden Investment- und Asset-Management-Knowhow. Als Capital Bay bieten wir Investoren einen Rundum-Service von der Grundstücksakquise und Baurechtschaffung über die Fremdkapitalbeschaffung bis hin zur Vermarktung und Bewirtschaftung der Projekte. Durch die Anbindung an unsere Betreiberplattform sichern wir nicht nur den Bau, sondern auch den operativen Betrieb der modularen Immobilien.

We offer investors complete investment solutions with customized operator concepts for various target groups and ensure optimum performance and long-term success.

The advantages at a glance

Faster

More sustainable

at a fixed price

from the world market leader

Top credit rating

Made in Germany

Projects in implementation

Coming soon

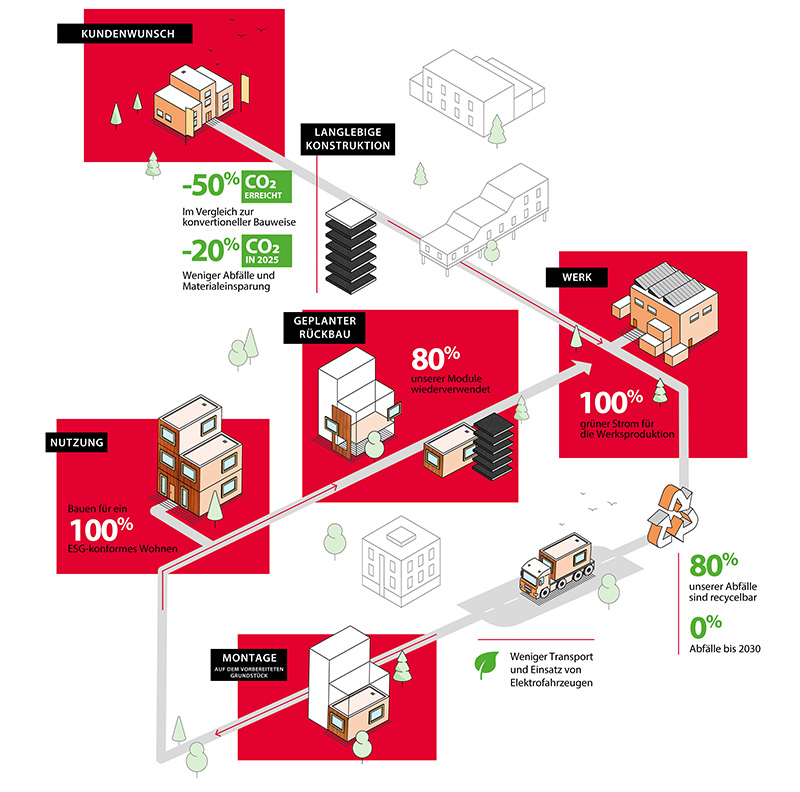

Zirkulär & modular

Industrialized, modular construction means building in a circular and demountable way. This has advantages for people and society. Just like conventional buildings, our modular housing solutions last for decades. Instead of demolishing them at the end of their life cycle, we reuse the components.Often in a different location, with a different layout or shape. Daiwa House Modular Europe's housing solutions are therefore circular and future-proof, whatever the future may bring.

Complete apartments are realized in our own factory

Regardless of the weather, the living modules in the

Daiwa House Modular Europe factory. Welding robots join the steel profiles, 90 percent of which are made from recycled steel. Completely prefabricated bathrooms and kitchens are installed and connected in the factory. Windows are also installed at the factory.Each module is given a QR code and can be identified and traced at any time, and the materials used are traceable. Production at the factory is powered by 100% green electricity. At the project site, we assemble the parts into one of our housing solutions.Assembly on the construction site takes place every 30 minutes: an apartment is installed ready for occupancy every half hour. This type of construction goes beyond prefabricated construction, where only loose components are produced in advance.

This is the kind of fast, modern and social construction that we urgently need and are driving forward for our city: With over 1,400 new apartments, Gewobag is creating an attractive neighborhood in Lichtenberg with affordable rents and a wide range of offers for the neighborhood. Today we are laying the foundation stone for this. Thanks to sustainable modular construction, a new residential quarter is being created within a very short space of time that is exemplary for resource-saving construction.Students, families and pensioners will find their new homes here. Only if we focus more on modular construction will we achieve our housing construction target of 200,000 apartments by 2030. (Laying of the foundation stone at Landsberger Allee 341-343 on 27.01.2023)

Franziska Giffey

I see great potential in serial and modular construction for Germany, particularly in the area of affordable housing. That's why we need to take this construction method out of its niche and make it more widespread. With the planned harmonised type approval for the state building regulations, which is to be introduced as part of the acceleration pact, the approval processes for construction projects can be significantly simplified. We have also launched a funding programme with a sum of 2 billion euros for the climate-friendly construction of new homes in the low-price segment. This is also an important prerequisite. This can give a boost to modular construction.

Klara Geywitz

Smart concepts are needed to master the urban planning challenges - and we deliver them: Thanks to the modular construction method, the quarter can be realized much faster and more gently - at the same time, we are strengthening the regional economy, as the central modules are produced next door in Brandenburg. (Laying of the foundation stone at Landsberger Allee 341-343 on 27.01.2023)

Markus Terboven

Development

Strategic Dialogue in Cork: Why Ireland's housing construction is driving the economy

District Administrator Frank Steffen visits modular construction factory: the future of modular construction in Fürstenwalde

Serial and modular construction: Where things still get stuck

Find out more about the investment opportunities in the joint venture. Our aim is to develop the optimum overall product comprising financing, construction, letting and sales - taking into account exactly what is crucial for you.